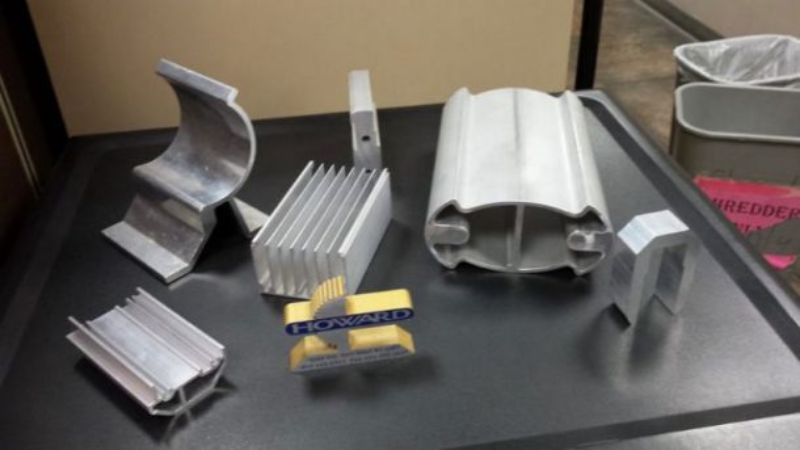

As with any component or part, there are often a lot of different options for using the material in a unique design or innovative way. T channel and T-slot channel is no different, with the range of custom extrusions and the option to customize extrusions, this is a very versatile aluminum component.

From the very basic t-shape bar to the more complex T slot systems, there is really no limited as to what you can use this material for. You will find these T slot used in construction, marine applications, in building frames and work tables, mobile cars and even in furniture and on production lines to create stock and customized components, parts and systems.

Universal or Custom

Buying T channel and T-slot components start with considering if a universal or standard extrusions or a custom extrusion is the best option. Weighing the pros and cons of each choice, particularly if you are looking at a lot of manufacturing or fabrication with the material is an essential consideration.

The biggest plus to using a stock, standard or universal T slot extrusion is that it will match with any other component designed for that size. In other words, you will have greater freedom in shopping around, comparing prices and not having to worry about components not fitting correctly or simply not looking the same.

The drawback to this is that using the stock or standard T channel extrusion may limit your creativity and design options. Simply reworking the design may be all that is needed to accommodate these minor differences.

Custom extrusions are more costly to make, but allow you to have just the shape, size and profile the project calls for. It will also mean that future orders will have to be managed as it isn’t a shape that is going to available other than from the company you worked with to develop the die and produce the extrusion.

Type of Use

Buying from a quality seller specializing in custom aluminum and stock aluminum components used in retail displays, fabrication, manufacturing and in specialized industries such as vehicle manufacturing and furniture manufacturing ensure the product will be top quality.

Ask about the option for finishing on the T-slot systems or components you are considering. This is true for both stock as well as custom extrusions you may need. Working with one company through design to final production of the parts makes everything easier, decreases lead time and even helps to manage costs.